Environmental incidents and emissions

As part of our management systems we record incidents (occurrences noted by our own staff which may or may not have led to a complaint) and complaints (arising from external sources).

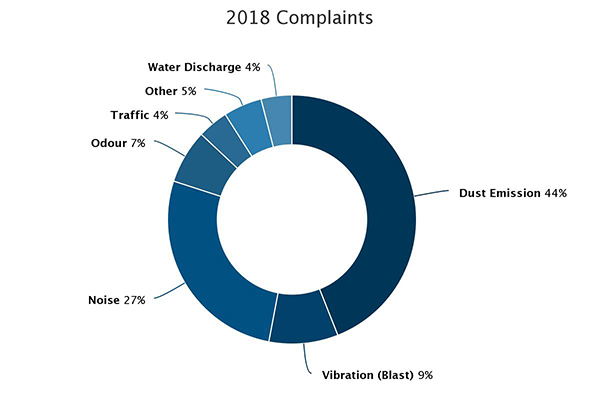

The number of incidents fell from 287 to 236, reflecting ongoing improvements in plant efficiency, while complaints fell to 127, the lowest level for five years and very close to our target of 123. Dust was again the most common cause of complaints (44 per cent) but we expect to see an improvement in this area following major investments at all our cement and Regen works and further investments in wheel washing and dust suppression equipment at our quarries and concrete plants.

Environmental management is included in our specialist IEMA training programme for managers (see employment and skills).

-

Incidents, complaints and prosecutions

2010 (baseline)

2016

2017

2018

Incidents

167

233

287

236 Complaints

286

214

143

127 Prosecutions

1

0

0

0

Target: 10 per cent year-on-year reduction in complaints based on 2010 figures.

Emissions from cement production

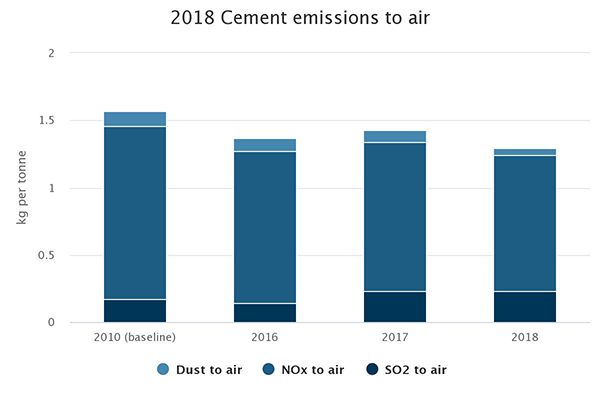

Emissions of dust, oxides of nitrogen (NOx) and sulphur dioxide (SO2) from our three cement plants were again well below the industry targets set in 2015. SO2 emissions remained above the historic low recorded in 2016. These emissions are related to the presence of volatile sulphur compounds found in the quarried raw materials and vary depending upon the part of the quarry that is being used. A new gas scrubber on the main stack at Ribblesdale cement works in Lancashire has reduced average monthly SO2 emissions by around two-thirds since it was commissioned in June 2018. The benefits of this £8.5 million investment will be seen in our 2019 report.

Dust emissions from cement production fell by almost a half in 2018 and are now well below our 2020 target. The latest reduction resulted from investments totalling £15 million made in the prior year on fabric filters for the cement mills at both Ketton and Ribblesdale and the more recent replacement of the kiln filter at Ketton and the gas scrubber at Ribblesdale. Commissioning of a new cement grinding mill at Padeswood in March 2019 to replace two ageing units will ensure these improved dust emission levels are maintained.

NOx emissions were at the lowest level on record and well within both our 2020 target and the industrial emissions directive best available techniques (BAT) conditions of 450 mg/Nm3 set in April 2018.

We publish annual reports of cement plant emissions on our website at www.hanson.co.uk.

-

Cement specific emissions - kilogrammes per tonne

2010 (baseline)

2016

2017

2018

Dust to air

0.11

0.10

0.09

0.05 NOx to air

1.29

1.13

1.11

1.01 SO2 to air

0.17

0.14

0.23

0.23