Energy efficiency

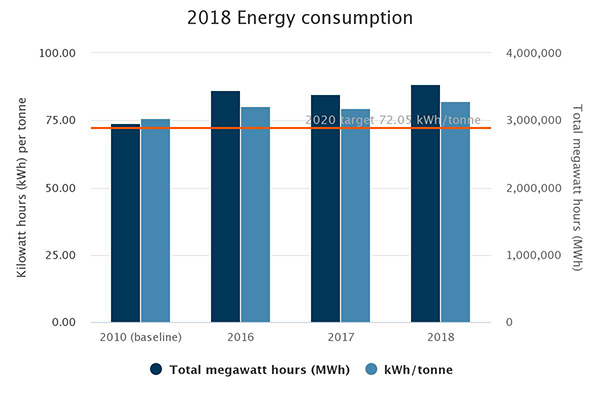

Energy consumption in the aggregates division fell, but increases in cement, Regen and asphalt production saw total energy use rise by 4.6 per cent. Energy use per tonne of product rose by 3.1 per cent, heavily influenced by a fall in demand for ready-mixed concrete, which has the lowest energy intensity of all our products. There was also an increase in marine dredger fuel consumption due to weak demand on the south coast and the need to relocate the vessels.

To overcome the changes in product mix, our ISO 50001 systems normalise production levels to a known baseline output. When the 2018 data is normalised to the same product mix, we have improved on the 2010 figure of kilowatt hours per tonne by 0.7 per cent, but are still behind our 2020 target.

We continue to invest in new technology and embed both best practice and energy awareness into the business. We run continuous improvement programmes and encourage employees to enter good ideas into our opportunities database or share them through the sustainability working groups.

We are also investing in our plant and machinery to improve efficiency. A new cement grinding mill at Padeswood cement works in north Wales will deliver a 30 per cent reduction in electricity consumption for this part of the process. And new bag filters on the mills at Ribblesdale and Ketton cement plants will reduce power consumption and improve thermal efficiency.

Our contracting division set a national target to use less than 0.565 litres of fuel in its surfacing machinery for every tonne of asphalt laid and ended the year at 0.521. A key factor was the procurement strategy to hire equipment on long term leases which allow new-for-old replacements every three or four years.

-

Energy consumption

2010 (baseline)

2016

2017

2018

% change since 2010

% change since 2017

Energy consumption – kilowatt hours per tonne

75.84

80.40

79.73

82.21 8.4%

3.1% Energy consumption – total megawatt hours

2,964,572

3,456,773

3,388,605

3,543,967 19.5%

4.6% When normalised for production changes at business line level, the 2018 performance is 72.5 Kwh/tonne against a 2010 baseline of 73.0 Kwh/tonne, showing a reduction of 0.72%.