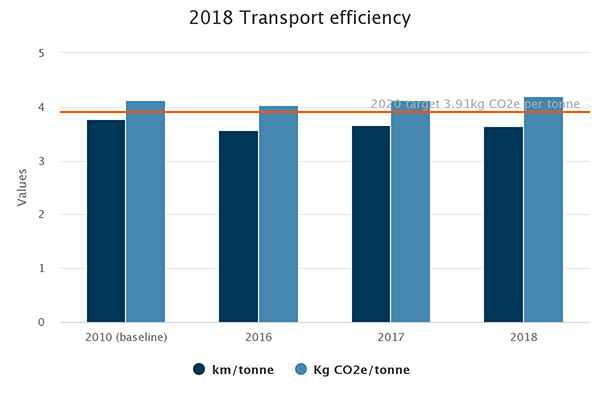

CO2e emissions from transport

CO2e emissions from transport on a per tonne basis rose by 1.8 per cent during the year. This was principally due to an increase in the government’s emission factors for road transport and an increase in delivery distances for asphalt. We now have a higher percentage of our own vehicles meaning we can track fuel use more accurately and provide fuel efficiency training for all our drivers.

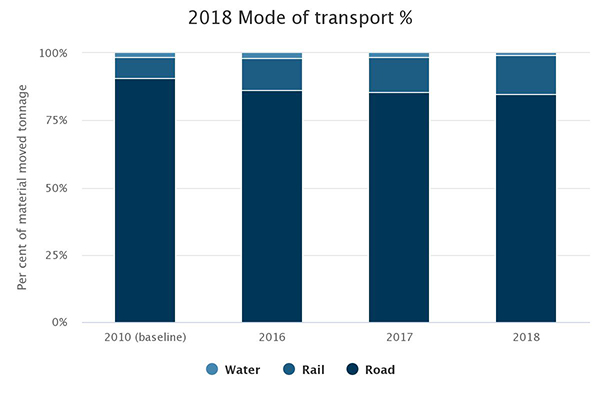

Rail deliveries rose to 14.4 per cent and will increase further as investments linked to our strategy to reduce road deliveries come on stream. We re-opened the single-track rail link into Tytherington quarry in South Gloucestershire at the end of November after a break of more than 15 years and spent £250,000 restoring the railway siding into Ashton-in- Makerfield depot in Greater Manchester which had been disused for a decade.

Stone extraction at Tytherington re-started earlier in the year, six years after the quarry was mothballed during the recession. We plan to operate up to five trains a week to depots across the south of England depending on demand and expect the quarry to play an important part in the supply of materials to HS2 – the new high speed rail link between London, Birmingham, Manchester and Leeds.

Three trains a week are delivering stone to Ashton-in- Makerfield from Shap quarry in Cumbria, taking around 1,500 truck journeys off the road each year and reducing road delivery distances by around 500,000 miles a year.

In the next few months the installation of three new cement silos alongside the existing railway line at Padeswood cement works in north Wales will be completed, allowing up to three trains a week to be loaded for deliveries to Hanson depots at Kings Cross, (London), Avonmouth, (Bristol) or Belshill, (Glasgow) depending on demand. At present the rail link is only used to bring in coal to fire the kilns.

Cement has been railed into Bellshill since 2007, saving over 48,000 HGV movements. A £1.1 million investment completed in April 2018 means it can now store more cement and also distribute Regen (GGBS) delivered by road from the Teesport works. The site has three silos - two for cement and a third for Regen.

A project to optimise order handling and vehicle scheduling in the aggregates, asphalt and concrete business lines is ongoing. The aim is to improve vehicle use and reduce fuel costs. The project is focused on the effective and efficient use of our delivery fleet through the introduction of vehicle optimisation software, GPS and a material resource planner (MRP) to schedule internal deliveries.

-

Transport efficiency

2010 (baseline)

2016

2017

2018

Tonnes delivered

29,529,302

30,027,466

32,281,642

34,096,102 kg CO2e / tonne

4.12

4.03

4.13

4.20 Total distance travelled km

111,580,638

107,116,583

118,220,238

124,365,125 Tonnes CO2e / year

121,589

120,878

133,237

143,291

-

Mode of transport

2010 (baseline)

2016

2017

2018

Road

90.78

86.13

85.55

84.74 Rail

7.91

11.89

13.11

14.37 Water

1.31

1.98

1.34

0.89